FULL WELDING POSITIONERS

Full welding positioners or manipulators allow the operator to have maximum weld accessibility for a tack welded component. Orbit designed positioners support maximum operator comfort with proper electrical controls. Safety is at most important while operating loaded positioners. Safety curtains support operator safety as well as functioning of positioner. In most of our full welding positioners , job comes to operator than operator going to welding spots. Properly balanced job rotation axis is prime concern in all our full welding positioners. Optimum Load capacity, height of rotational axis from ground, required rpms , power ratings and required torque are all specifications most suitable for a full welding positioner. We at OMTT meet this requirement quite successfully with cost effective solutions.

.

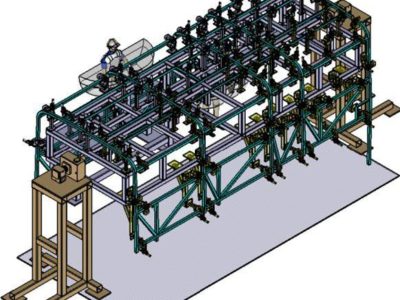

BUS FRAME ASSLY

AND WELDING

CABIN BASE

WELDING POSITIONER

CABIN SIDES WELDING

POSITIONER

2- AXIS FULL WELDING

POSITIONER

MAIN BEAM FULL WELDING

POSITIONER

OIL TANK FULL WELDING POSITIONER USA

COUN WT

FULL WELD

DUMPER BODY BOTTOM FULL

WELDING POSITIONER

DUMPER BODY CANOPY FULL WELDING POSITIONER

DUMPER BODY FRONT FULL WELDING POSITIONER

DUMPER BODY FULL WELDING

POSITIONER

DUMPER BODY SIDE FULL WELDING POSITIONER

EXACAVATOR BOOM FULL WELDING POSITIONER

EXACAVATOR TRACK FRAME FULL WELDING POSITIONER

DUMPER BODY SIDE-FULL

WELDING

MAIN BEAM FULL WELDING POSITIONER